Asphalt experts recommend parking lot sealcoating within the first year of your asphalt installation and re-sealing about every three to five years after that. But, what exactly is sealcoating, and why is it so important?

In this article, we will explain what parking lot sealcoating is and why it is so universally suggested.

Asphalt Parking Lot Basics

Before you can understand how asphalt sealcoating benefits your parking lot, you need to understand a little bit more about the properties of asphalt itself.

Asphalt cement has been used in road construction for centuries. While natural deposits of rock asphalt exist, today, most asphalt cement is distilled during the oil refining process. As a binding agent, asphalt is versatile, waterproof, durable, and resistant to most salts, acids, and alkalis.

Today’s asphalt pavement contains two primary ingredients: asphalt cement and aggregates. Asphalt cement makes up just five to ten percent of the mixture by weight. The majority (90 to 95 percent) is aggregate. Aggregates, also called mineral aggregates, are hard, chemically inert materials. For instance, gravel, rock dust, and sand are all used. To create the final product, aggregates are mixed with asphalt cement. This final product is called asphalt concrete, but is referred to as asphalt, for short.

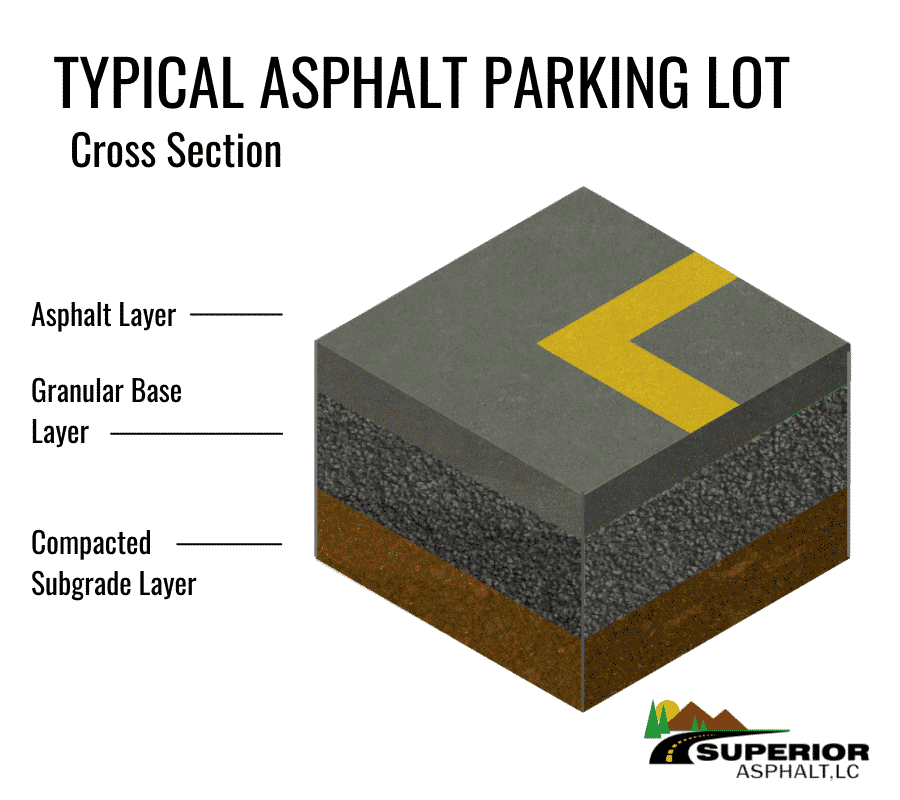

Typical asphalt pavement systems have three layers: a compacted subgrade layer, a granular base layer in the middle, and the upper layer of asphalt pavement. This upper layer is the part that we see on top. This layered structure is essential. A pavement system has to take the brunt of vehicle load while remaining somewhat flexible to environmental changes.

Threats to Asphalt Pavement Systems

Asphalt pavement systems are strong and flexible. But, they are not indestructible. Here are a few things that have the potential to deteriorate either asphalt itself or the entire pavement system.

Petroleum Products

Asphalt’s chemical makeup makes it susceptible to breakdown from petroleum products, like vehicle oil.

Water, Snow, Ice, and Frost

While asphalt’s adhesive capabilities stand up to water, pavement systems’ deterioration accelerates when water flows into cracks. The base and subgrade are susceptible to water washing them away. If it doesn’t wash away but freezes when the temperatures drop, it can expand in small cracks, making them wider and opening the asphalt, base, and subgrade up to more deterioration.

Cars and Regular Traffic

Prolonged vehicle load and friction over the surface lead to natural asphalt deterioration over time. Vehicle load that’s too heavy for the base and subgrade can cause cracks and depressions.

Air and Sun

Asphalt changes with age due to prolonged exposure to the elements. As soon as pavement installation is complete, asphalt begins to harden because natural oils react with the air and evaporate. If left to oxide for too long, the pavement turns from hard to brittle. To keep oils intact and seal the whole pavement system, you should apply asphalt sealcoating sometime after 90 days but within the first 12 months.

Parking Lot Sealcoating

Emulsion seal coat is a pavement surface treatment. It’s applied via spray or squeegee. This viscous liquid contains a mixture of the following:

- Aggregate

- Surface active agents

- Catalysts

A thin layer of sealcoat is spread (or sprayed) onto the asphalt. The mixture’s liquid immediately starts evaporating. The result is a coating of chemicals and aggregate, bound to the asphalt’s surface. While it only increases pavement volume by less than 1/8th inch, this layer has some pretty important characteristics. Sealcoating is soft and flexible. When properly applied and allowed to cure, it can protect your asphalt and prolong its useful life.

3 Reasons Why Parking Lot Sealcoating is Vital

It is essential to seal your asphalt parking lot. Here are three big reasons why:

1. Sealcoating Keeps Asphalt From Becoming Too Brittle

When not sealed, asphalt pavement oxidizes. It can oxidize to the point that it becomes too brittle. If it gets too brittle, asphalt readily cracks with regular traffic. And cracks lead to more cracks.

2. Sealcoating Protects Asphalt From the Elements

If left unsealed, not only will asphalt oxidize, but it will be vulnerable to other threats. The following are things that threaten to interact with asphalt and cause deterioration:

- Water

- Vehicle fluids

- UV rays

- Road salts

3. Sealcoating Replaces Lost Surface Materials

Asphalt emulsion seal coat fills in surface voids where aggregate has come loose from the asphalt. Sealcoat adds fine aggregate for a smoother-looking surface. The renewed surface aggregate also provides texture. This added texture offers traction for pedestrians and vehicles.

Asphalt Parking Lot Sealcoating in Utah

Timely and proper seal coat application can slow deterioration and preserve asphalt’s condition. But, a seal coat job will mirror the shape of the pavement it covers. Wondering whether your asphalt is a viable candidate for our sealcoating services? Superior Asphalt, LC can help. Contact us today!

Read More About Sealcoating: